Telia and partners introduce new 5G AI solution for industrial use

ABB is piloting the world’s first industrial artificial intelligence application using 5G technology to assist the assembly of drives at its Helsinki plant.

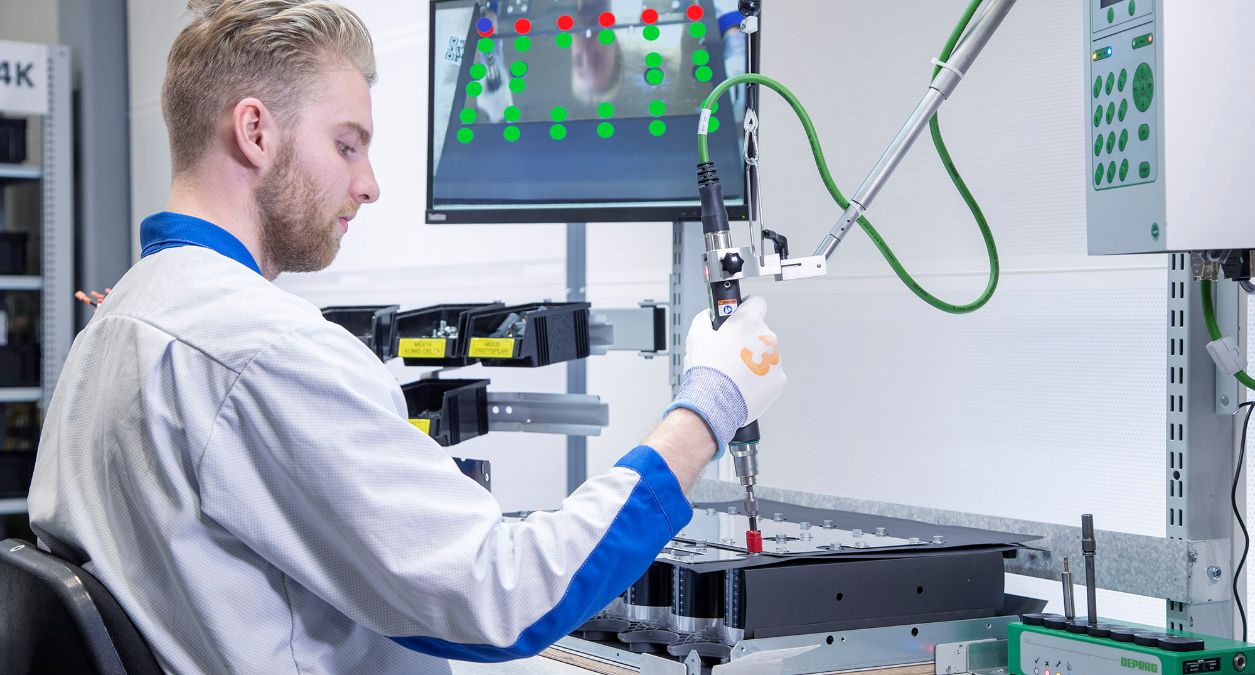

The AI application will support the plant’s workers by monitoring the assembly of the drives by camera and ensuring they are correctly assembled according to a customer’s order and applicable work instructions.

The fast 5G connections will provide workers with real-time feedback, making assembly significantly easier than following work instructions from a paper document, thereby helping to improve quality.

Atostek, which specializes in industrial applications, is responsible for the computer vision and the AI application. Telia is providing the system’s high-speed 5G mobile connections and the computing capacity needed by the application in its data center. The project is being implemented in stages and will be in full-scale production in June 2019.

The application is being applied to the power module assembly line, which is critical to production quality and demanding for employees as dozens of different versions of the same product are assembled on the same line.

“The potential of AI is strongest when combined with human expertise, and the goal of supporting em-ployees in a new way is at the heart of this project,” says Simo Säynevirta, Country Digital Lead at ABB Finland. “At its best, this real-time quality assurance system not only improves production line quality and productivity, but also reduces the stress associated with human errors, which helps improve wellbeing at work.”

5G enables wireless technology to be applied much more widely than has so far been possible and this is expected to significantly boost global production over the next few years. By introducing the 5G AI solution, ABB and its partners are exploring how industrial applications that require high data capacity and high computing power can be implemented in scalable form in the future, regardless of location. For ex-ample, the AI application could be integrated with enterprise resource planning systems.

”The 5G solution built for ABB is a prime example of the drivers speeding up the next industrial revolu-tion: superfast connections, cloud services powered by our data center and analytics. They accelerate the digitalization of the customer’s industrial process in a way that on the national level means a significant increase in competitive competence and productivity,” says Janne Koistinen, Head of 5G Program, Telia Finland.

About ABB

ABB’s drives plant in Helsinki is ABB’s leading unit in the development of low voltage drives. The plant has around 1300 employees. Globally, ABB’s drive business involves around 6,000 employees in a total of over 80 countries.

Cookie notification

Cookies allow us to optimize your use of our website. We also use third-parties cookies for advertising and analytics. Please read our Cookie Policy for more information.